We provide consulting at every stage of an abatement project, including :

project design/specifications - project management - site supervision - air monitoring.

Project Specifications

Bersch Consulting Ltd. provides written technical specifications for hazardous materials abatement projects involving: Asbestos, Mold, Lead, and PCBs. These are typically provided following a Hazmat Survey.

We develop our specifications to meet the sustainability reporting requirements of Occupational Health & Safety Regulations and industry specific standards.

Asbestos Abatement

Asbestos Site Supervision, Inspections and Air Monitoring

Site supervision and inspections are an integral part of our services during hazardous materials remediation to ensure quality control for our clients.

We have the equipment and resources to provide site supervision and air monitoring as per the NIOSH 7400 Method that is the acceptable standard in the Province of Saskatchewan. On-site inspections and air monitoring provide quality control for the client to ensure work procedures and equipment implemented during asbestos processes meet Occupational Health & Safety Regulations and industry specific standards.

Our Asbestos Abatement Process

Throughout asbestos abatement projects we submit daily air monitoring bulletins to the owner identifying fibre levels recorded, work activity, and any comments and concerns for the work shift being monitored. Upon completion of asbestos abatement activity, we conduct final visual inspections and air clearance to certify that the area is suitable for occupancy by staff and patrons of the facility.

Mold Abatement

Bersch Consulting Ltd. has the equipment necessary to conduct air monitoring and bulk sample analysis pertaining to mold related issues within facilities. We collect air samples via Air-O-Cell cassette method to determine airborne mold spore counts. This non-culturable method of sampling draws a measured volume of air through the cassette. This method allows for the collection of all spores (both viable and non-viable) and particulate matter in the air.

This method of analysis offers the advantage of identifying both viable and non-viable mold spores and providing a quick turn-around-time (TAT) for rush analysis. We collect and analyze swab and bulk samples in accordance with Microscopic Examination of Fungal Spores, Fungal Structures, Hyphae and Other Particulates from bulk samples. The Direct Examination is a useful tool in quickly identifying spore types present in building materials. The analytical method indexes the spores identified relative to general industry standards rather than quantifying the spores.

Bersch Consulting Ltd. works with a NVLAP accredited laboratory for partner sample analysis. TAT for mold air sample analysis can be obtained within 24 hours if RUSH analysis is requested. Bulk samples for mold are also sent to a NVLAP accredited laboratory.

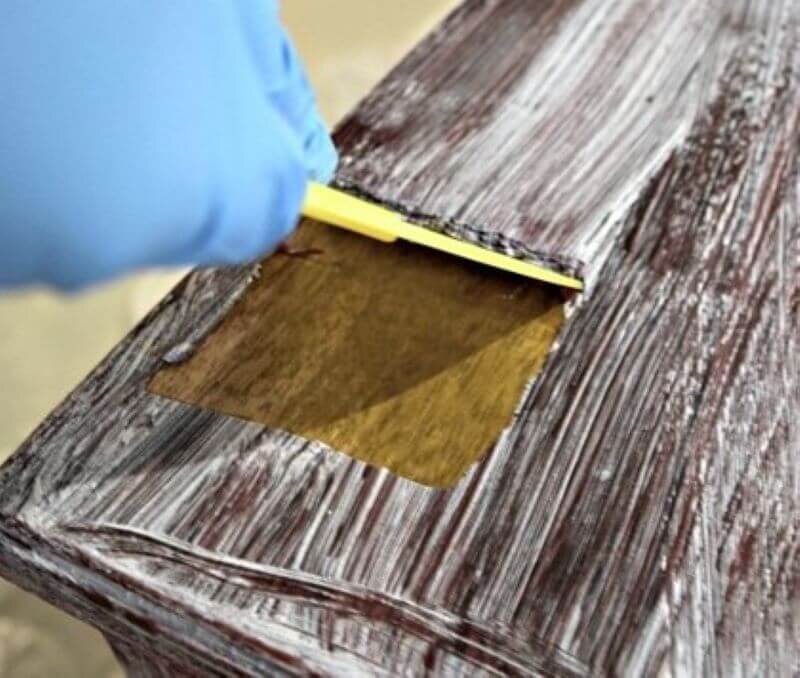

Lead Abatement

Bersch Consulting Ltd. has the equipment necessary to conduct air monitoring and bulk sample analysis related to lead issues in facilities. We collect and analyze air samples as per the NIOSH 7082 to determine lead concentration in air.

We compare TWA’s to contamination limits based on airborne particulates established by Occupational Health & Safety Regulations of the Province of Saskatchewan.

Employers’ Responsibilities Related to Lead

When performing renovations or demolition activity that may generate respirable lead particles the employer has an obligation to ensure workers are not exposed to elevated contamination limits as identified in Table 21 of the OHS Regulations. Buildings constructed prior to late 1970’s are highly suspect of containing lead based paints. If paint is not analyzed for lead content it is acceptable to treat/handle as lead containing and ensure workers are protected with adequate PPE to ensure no exposure.

Welding, cutting, grinding, or torching of surfaces on steel that contains as little as 130mg/kg of lead can release airborne lead levels as high as 0.8mg/m3 (16 times the exposure limit). The control measures and respiratory protection required for working with lead paints and coatings is determined by the risk level assigned to a specific activity.